5 Robots from Berlin

From elephant-trunk arms to medical drones: Berlin's startups are building the autonomous machines of tomorrow.

Berlin takes a leading position in the development and application of robotic systems. The capital actively promotes research in robotics and provides a platform for collaboration between scientific institutions and industry. More than 35 Berlin research institutes and over 140 technology companies are at the forefront of developing innovative robotics solutions for various sectors including manufacturing, medical technology, and logistics.

From industrial automation to service robots, Berlin's robotics scene tackles real-world problems with precision and creativity. These machines are intelligent, adaptable, and designed to work alongside humans.

Let's meet five remarkable robots that call Berlin home.

The Skillful Hand

What is its name? Our robotic manipulator is called Capandji Hand, inspired by the renowned French orthopedic surgeon and anatomist Adalbert Ibrahim Kapandji who is best known for his influential work in the field of functional anatomy.

What inspired you in its development? The Capandji Hand is the interface between mind and world: through it, we touch our environment, learn from it, interact with it, and shape it. It is by far the most important and versatile tool of humankind. By understanding its underlying principles and transferring them to robotics, we can unlock the full potential of machines—which at this point, mostly lack the dexterity and reliability of humans.

What is its greatest strength? Unlike traditional robotic hands, the Capandji Hand is not rigid, but compliant. This allows it to passively respond to its environment, facilitating robust grasping and object handling. And importantly, our hand does not hurt and does not break anything.

What doesn't it like at all? The Capandji hand does not like monotone tasks, as it is designed to enable a vast variety of everyday activities.

Which markets does it want to conquer? The Capandji Hand is an exceptionally versatile tool with virtually limitless applications. Its primary goal is to enable automation of existing processes without requiring complex modifications.

How autonomous is it? Thanks to its human-inspired intrinsic elasticity, the Capandji Hand offloads critical aspects of the control problem from software to hardware. This embodied intelligence enables robots equipped with the Capandji Hand to exhibit highly effective and reliable autonomous behaviors.

Which sensors does it use? The hand can measure the state of its elastic tendons and the position of its joints. This allows it to estimate the contact force exerted onto its environment, critical for dexterous interactions.

What is the next thing you want it to learn? The Capandji hand is still in its early stages of development. But thanks to its advanced control software, it is capable of learning from its own actions to continuously improve performance. Combined with its passive shape-adaptation capabilities, this makes the Capandji Hand exceptionally versatile and reliable.

The Elephant's Trunk

What is its name? AIRA (Artificial Intelligent Robot Arm)

What inspired you in its development? From day one, we talked to customers about what features they thought new robots should have. Based on their insights, we decided to start development. The movement is, of course, inspired by an elephant's trunk.

How tall and how heavy is it? The arm is currently 2 m long. The moving part of the arm weighs 4 kg, and the entire structure weighs approximately 30 kg.

What is its greatest strength? Its strengths are: very high flexibility, significantly lower weight and thus increased safety, also thanks to its sensor technology. Because the arm is hollow on the inside, cables and hoses can be routed through it as required by the customer. In addition, the system can be easily scaled, allowing larger and smaller versions of the robot to be built with little development effort.

Which markets does it want to conquer? All markets in which manual work can be automated are conceivable for it. Especially where cooperation with humans or agility is required.

Which sensors does it use? AIRA can measure the load on the arm very precisely. Thanks to lidar sensors, it recognizes its surroundings and avoids obstacles. A camera can be mounted depending on the application scenario.

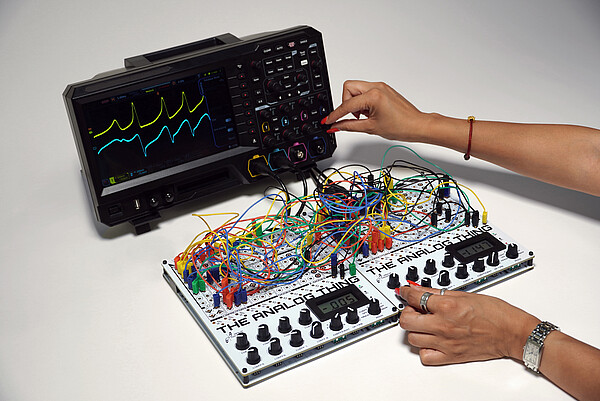

The Valiant Little Tailor

What is its name?SWNG-BRG

What inspired you in its development? The increasing shortage of skilled workers in the textile industry and the realization that we in the textile industry need to develop turnkey automation solutions for sewing ourselves. We took our cue from the high-precision processes used to assemble cars and manufacture modern prostheses—modular, adaptable, and efficient.

How tall and how heavy is it? The sewing robot itself is approximately 50 cm high and requires hardly any additional space at an existing sewing workstation. The cell (enclosure) is about the size of a refrigerator. Both are mobile and can be easily moved with a pallet truck.

What is its greatest strength? Its great strength lies in its ability to automatically and precisely guide and process all kinds of limp textiles—a challenge that even the most modern industrial robots have failed to meet so far.

Which markets does it want to conquer? It is particularly in demand in the manufacture of clothing, home textiles, medical textiles, and technical textiles wherever there is a shortage of skilled sewing staff due to a lack of skilled workers—in Germany, Europe, North America, but increasingly also in Asia. It also supports the relocation of textile production closer to the customer and helps to avoid production downtime due to staff shortages.

How autonomous is it? It is designed to sew completely autonomously after training—provided it is always supplied with sufficient material. One person can load, monitor, and maintain several robotic sewing cells at the same time. This reduces the workload for sewing staff, giving them more time for other activities such as quality assurance or process monitoring.

Which sensors does it use? High-resolution cameras with intelligent image processing help to accurately recognize different textiles, analyze their type and shape, and even assess seam quality in real time.

The Diligent Painter

What is its name? MalerRoboter (painting robot)

What inspired you in its development? The increasing shortage of skilled workers in the construction industry and the desire to reduce physically demanding work in order to relieve workers and reduce health risks are key issues. At the same time, we want to make traditional skilled trades more attractive to the next generation with modern technology and contemporary features.

How tall and how heavy is it? It is approximately 1.90 meters tall, compactly built, and weighs a total of 130 kilograms, with the mobile platform being the heaviest single component at 66 kilograms. The robot can be disassembled into four parts (arm, mobile platform, battery, and airless device), making it manually transportable and easily fitting into a small van.

What is its greatest strength? It can coat large, monotonous wall surfaces and ceilings independently and evenly; efficiently, precisely, and with consistent quality. It is also the lightest painting robot on the market and fits through any standard door.

What doesn't it like at all? Complex room geometries with many edges, protrusions, or tight corners are not (yet) its favorite environment.

How autonomous is it? It automatically recognizes rooms and uses AI to identify obstacles such as doors, windows, or radiators, which are then avoided when spraying. After entering the floor plan (without dimensions) into our app, all you have to do is press "Start" and the MalerRoboter will take care of the rest on its own.

The Medical Courier

What is its name? Labfly

How big and how heavy is it? The Labfly is 1x1m in size and weighs 8kg including 1kg payload capacity.

What is its greatest strength? The Labfly transports laboratory samples or medications between hospital locations. Traffic-independent and fast via direct route.

What doesn't it like at all? The Labfly doesn't like icing conditions. Temperatures between -4 and 2°C combined with high humidity are conditions in which it very reluctantly operates.

Which markets does it want to conquer? The Labfly wants to reimagine medical logistics. In addition to transporting laboratory samples for hospitals, it also wants to transport medications from wholesalers to pharmacies and later also from pharmacies to patients.

How autonomous is it? The Labfly flies completely automatically and is monitored centrally from Berlin by an operator. However, the Labfly can fly anywhere in Europe.

Berlin: Where robots come to life

These five innovations represent just a glimpse of what's happening in Berlin's robotics scene. From hands that feel to drones that heal, the city is proving that the future of automation is both practical and remarkably human-centered.

What makes Berlin special isn't just the technology—it's the ecosystem. The city brings together world-class research institutions, ambitious startups, and established companies in an environment that encourages experimentation and collaboration. Whether you're developing surgical robots or painting machines, Berlin offers the perfect blend of technical expertise, creative energy, and supportive infrastructure.

The robots of Berlin aren't just solving today's problems—they're building tomorrow's solutions. And they're doing it with a distinctly Berlin attitude: innovative, pragmatic, and just a little bit rebellious.

Ready to join the robotics revolution? If you want to learn more about robotics in Berlin, feel free to contact Jens Woelki from Berlin Partner anytime. Berlin Partner is the city's economic development agency. They'll support you free of charge if you want to engage in business in Berlin. Also visit the our website to discover more about Berlin's thriving robotics ecosystem.

The future is being built here. One robot at a time.

---

Header image: Berlin Partner / Reve AI